Table of Contents

- What Are Gas Detector Tubes?

- When to Use Gas Detector Tubes

- What Gases Do Gas Detector Tubes Test For?

- How Do Gas Detector Tubes Work?

- How to Use Gas Detector Tubes

- How to Solve Problems With Gas Detector Tubes

- Pros of Gas Detector Tubes

- Cons of Gas Detector Tubes

- Choosing the Right Gas Detector Tube

Gas detector tubes provide you with an easy-to-use method of testing for a variety of gases. You don't need extensive chemistry knowledge to use these tubes or interpret the results. From xylene to carbon monoxide, you can use gas detector tubes to look for the presence of gases. These tubes prove you can use efficient materials to get fast results when measuring air quality.

What Are Gas Detector Tubes?

Gas detector tubes are an excellent way to get initial readings for gases around sites where air quality is a concern. Chemical spills, fires and gas leaks all can contaminate the air. Gas detector tubes make it easier to see whether toxic substances remain in the air near the site of the incident.

To use gas detector tubes, you also need a sampling pump. This pump requires no electricity, making it ideal for field use. You will need a means of transporting the tubes to the site safely, but the tubes need nothing more than the pump to take a reading and interpret the results. A color-coded guide on the side of the tube helps you read the concentration of gas the tube detected.

When to Use Gas Detector Tubes

Gas detector tubes measure concentrations of specific gases in the air. The amount found depends on the particular glass container you use as even those for the same gas will measure different parts per million (ppm) of the gas.

Some gases can be toxic to people who inhale them. Since not all gases produce immediate effects, those working in the area could breathe in the gas without knowing it, only to have serious health consequences later. To prevent this, test for the likeliest gases in areas where you suspect dangerous levels to occur. For instance, after a chemical leak, you may need to measure the air for excessive levels of the leaked chemical to determine when workers can safely return to the area.

Another use of gas detector tubes is to measure for adequate levels of oxygen. In some working conditions, excessive airborne particles may reduce the amount of oxygen in the air. To prevent hypoxia in workers, you may need to regularly test that the area has enough oxygen for a safe and comfortable work environment.

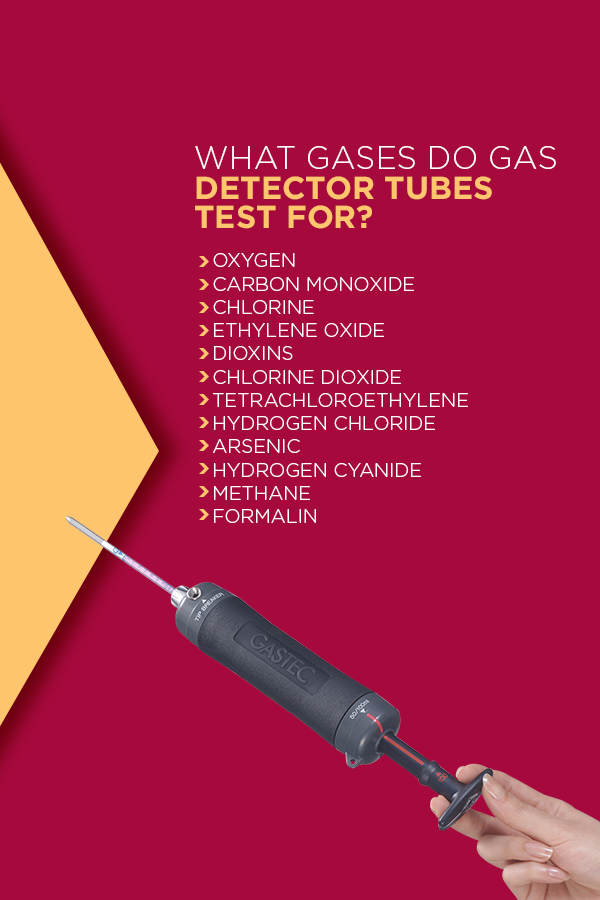

What Gases Do Gas Detector Tubes Test For?

Gastec gas detector tubes have options available to test for over 600 different gases. You will likely find a detector tube for the specific gas you need to monitor.

- Oxygen: Tubes can measure for adequate amounts of oxygen in enclosed, stagnant areas such as utility holes, sewers, storage tanks and silos. Atmospheric air contains about 21 percent oxygen while the human body has 65 percent. A lack of oxygen could lead to suffocation of workers in small spaces.

- Carbon monoxide: Carbon monoxide is colorless and odorless, so you must actively test for it to identify its presence. This gas often appears in facilities with fires because carbon monoxide occurs as a byproduct of combustion. Too much carbon monoxide can prevent workers from getting enough oxygen, and high levels of carbon monoxide exposure may be fatal.

- Chlorine: Water treatment facilities and swimming pools regularly use chlorine to prevent bacterial growth in the water. Exposure to chlorine gas at more than 14 ppm can be fatal when inhaled.

- Ethylene oxide: Usually, gas detector tubes will measure ethylene oxide to look for high concentrations indicative of a leak. For testing amounts of this gas in ambient air, use solid sampling or another measuring method.

- Dioxins: Dioxins are toxic in low concentrations, so a gas detector tube is useful at identifying their presence. Most often, dioxins form from the burning of oxygen, chlorine, hydrogen and carbon, as may occur with trash burning.

- Chlorine dioxide: Compared to chlorine, chlorine dioxide produces more severe side effects for people exposed to it. Though alone, chlorine dioxide is not flammable, it can readily combine with oxygen, increasing the chances of explosions or fires when it collects in an area.

- Tetrachloroethylene: Normally used as an industrial solvent, tetrachloroethylene can cause dizziness, nausea, loss of consciousness and skin and eye irritation. Testing for excessive levels of this substance helps ensure the safety of workplaces where it is in use.

- Hydrogen chloride: Hydrogen chloride more commonly occurs in the form of hydrochloric acid. This substance causes nose and throat irritation, in addition to coughing. High concentrations may be fatal. Many industrial facilities use this substance in the creation of medical supplies, etching fluids and much more. Any chemical plant where hydrogen chloride is part of the production process or produced should regularly test for this gas.

- Arsenic: Carcinogenic and toxic to the digestive system, arsenic has severe effects for those with exposure to it. When arsenic contacts an acid, the reaction produces a highly poisonous gas called arsine. Gas detectors should monitor for the presence of arsenic at semiconductor and insecticide plants, where arsenic is part of the production process.

- Hydrogen cyanide: Many industrial facilities use hydrogen cyanide for production. Ironworks and metal plating facilities frequently use this substance. However, exposure to just 110 ppm can be fatal after half an hour. Detecting this gas in the air in facilities that produce or use it could save the lives of the workers inside.

- Methane: Though methane does not pose a health hazard for people, this gas is highly explosive. Detecting amounts that could ignite in the air helps prevent fires.

- Formalin: Formalin occurs in many resins used for finishing in buildings. The fumes from these resins may cause coughing and eye irritation. Long-term exposure may result in kidney and liver problems. Many homeowners feel concern about the levels of formalin in their homes due to these resin fumes. The air quality industry is quickly recognizing this gas as a potential health hazard for people inside.

How Do Gas Detector Tubes Work?

Inside gas detector tubes are chemicals that react with the substance the device measures. After a one- to three-minute chemical reaction, the gas inside the cylinder changes color and rises to a marked level on the side of the tube to indicate the percentage of the detected gas in the sampled air in parts per million. Each tube uses a different substance to react with a particular gas. Because these chemicals rely on measuring certain chemicals and concentrations, you must use the appropriate detector cylinder when sampling an area.

How to Use Gas Detector Tubes

To use the gas detector tubes, you need a tube and pump from the same manufacturer. Steps taken to use the measuring cylinders are few, and the results appear after a short period. You will only require a small amount of time and effort to get results.

- Prepare the tube: Use the included tip breaker on the pump to remove both ends from the gas detector tube.

- Insert the tube: Push the pump handle all the way in. Insert the tube in the other end with the arrow on the tube directed at the pump.

- Align the pump: Turn the handle until the red guide mark on the top of the pump and the black mark on the handle align.

- Take the sample: Point the end with the tube toward the area you need to sample. Pull the handle to the halfway mark if you need a 50mL sample or all the way for a 100mL sample.

- Time the sample: Watch the white flow indicator on the handle. It will pop out when the sampling time has finished.

- Read the coloring: Remove the tube and look at the gauge on the side of the tube to get an estimate of the concentration of the gas.

Because using these tubes requires so few steps, almost anyone can use them. You can send out multiple people with pumps and tubes to gather air quality readings for a variety of gases in an area. The ease of use and speed of obtaining the results make gas detector tubes the best option for when you need to measure air quality without delay.

How to Solve Problems With Gas Detector Tubes

Several problems may arise during use, including unexpected results and concerns about the accuracy of the results. Proper storage and use of the tubes will prevent many common issues users face.

1. Correct Storage

The manufacturer Gastec instructs users never to freeze gas detection tubes, even those that require storage in cool temperatures. Look at the instructions for the particular tube to see if it requires refrigeration. For example, tubes that detect certain levels of chlorine, chloroform, carbonyl sulfide and carbon tetrachloride require refrigeration. The instructions are necessary, though, because tubes with a range of 25 to 1,000 ppm for chloride do not require storage below 50 degrees Fahrenheit, but chlorine detector tubes for smaller amounts such as 0.025 to 2 ppm need refrigeration. Even gas detector tubes that do not need refrigeration should stay in a cool, dry place until use.

In addition to storage conditions, consider the length of time you keep the tubes. Pay close attention to expiration dates because the gas detector tubes maintain accuracy only until they expire. Gastec does not ensure the accuracy of any results of expired tubes. When testing for air quality, you should use equipment that will return results you feel confident about. Because you cannot be sure of the results from expired gas detector tubes, never use them. Discard any expired tubes you have appropriately with other glass.

2. Proper Use

Proper use of gas detector tubes will prevent several issues with results. Never use a Gastec brand tube with any other maker's pump. The company designs its pumps and gas detection cylinders to work together for fit, sampling and timing. Always check the pump for a vacuum before taking a sample. If your gas detector tube did not change colors after sampling, the pump might not have created a vacuum.

When taking samples of air to measure for oxygen, the tubes will naturally warm due to the chemical reaction occurring inside. Keep your hands away from these detector tubes for at least two to three minutes after obtaining a sample to prevent burning your fingers. After this time, the heat from the oxygen detector tubes should dissipate enough to allow you to handle the part.

By following the directions for gas detector tubes, you will prevent many problems some people encounter with these measuring devices.

Pros of Gas Detector Tubes

Gas detector tubes work well when you require immediate results and cannot wait for a lab to process your sample. The speed you can have results returned make these tubes a better option than other means of monitoring air quality. If you need fast results after an incident, few other monitoring options will give you the speed and ease of use you need.

Another benefit of gas detector tubes is their ease of use. Almost anyone can quickly learn to take samples and interpret the results. You don't need chemistry knowledge to read the gauge on the side of the tube.

Compared to other methods of air quality sampling, gas detector tubes cost much less. Many tubes come in multipacks, allowing you to take several readings over time for one price. The pump required for taking a sample with these tubes is reusable, even if each tube only has a single use. Investing in a pump to use for these detector tubes allows you to take advantage of the lower priced sampling method detector tubes provide.

Cons of Gas Detector Tubes

Though gas detector tubes have many advantages, there are some drawbacks. First, the results may not have the accuracy you require. Check the individual tubes for information on standard deviation from accepted results. Additionally, other gases may interfere with the detection of the target gas.

Despite these minor disadvantages, gas detector tubes provide you with an easy way of determining the safety of an area without waiting for lab results.

Choosing the Right Gas Detector Tube

Each gas you test for requires a specific gas detector tube. You must know which gases you need to measure and the parts per million limits you consider safe. Detector tubes measure for ranges of gases, and if you don't use the right tube or sample size, you will not get accurate results.

The environment and any recent events will help you choose which tubes you need. For example, measuring ethylene oxide may be a part of a protocol for checking an industrial facility for leaks. Oxygen measurement may happen in areas with little air flow.

Understanding where these gas detector cylinders perform best starts with knowing the likelihood of encountering specific gases. This knowledge will make it easier for you to choose the right detector tubes.

Zefon International, Your Gastec Detection Tube Provider

Make environmental testing easier, whatever your field. Find the Gastec gas detector tubes for the substances you need to look for. We have hundreds of models that detect different gases in the air. Search for the Gastec gas detector tube you need quickly and easily at Zefon International. With so many options available for determining air quality, we are the professional choice for air sampling equipment.